Activity

Mon

Wed

Fri

Sun

Dec

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

What is this?

Less

More

Memberships

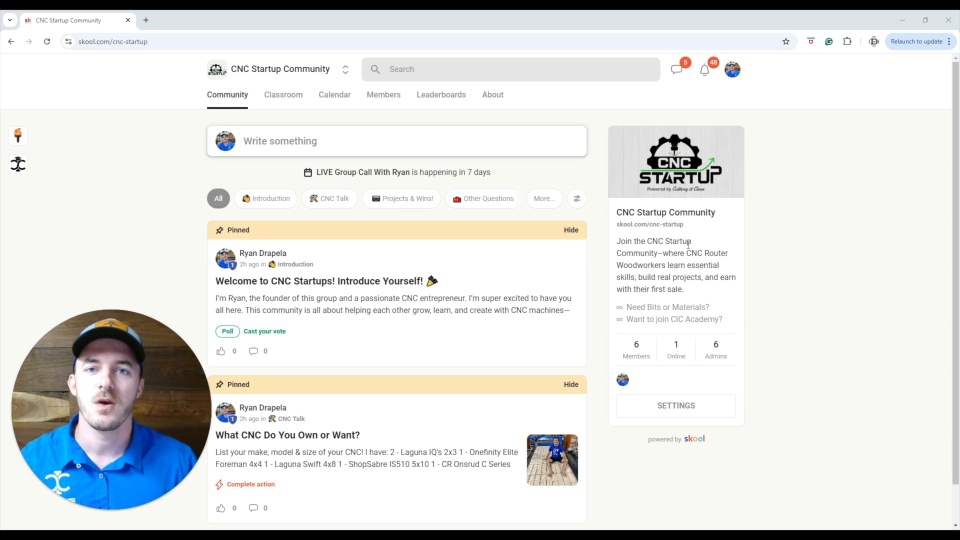

CNC Startup Community

Public • 115 • Free

4 contributions to CNC Startup Community

Welcome to CNC Startups! Introduce Yourself! 🎉

I’m Ryan, the founder of this group and a passionate CNC entrepreneur. I’m super excited to have you all here. This community is all about helping each other grow, learn, and create with CNC machines—whether you’re just starting or looking to take your skills to the next level. Here’s a little about me: - I’ve been working with CNC machines for 10 years, building a business and helping others do the same. - My favorite thing about CNC is turning a simple design into a product that people love. - Fun fact: I love Bourbon and Tequila, and have over 100 bottles in my collection/stash Now it’s your turn! In the comments, let us know: - Your name and where you’re from - What stage are you at in your CNC journey (just starting, hobbyist, business owner, etc.)? - What you’re most excited to create or learn with CNC - A fun fact about yourself! Looking forward to getting to know everyone and seeing what amazing projects we’ll create together!

Poll

35 members have voted

14

41

New comment 8h ago

2 likes • 5d

My name is Gregg Lungstrom and I retired in June of 2023 after 43 years of active duty Marine Corps and government contractor work. I have a 3018Pro desktop CNC which I have had since 2018 and just got it to carve after breaking down the G-Code. I have acquired a Standard Router Industrial 3 phase CNC in the last year and am currently working through the power conversion and vacuum problems. My goal is to have fun spending the next 40 years learning about all aspects of wood working. The CNC is just another tool I want to master.

Hello everyone

My Clinton jones, I'm base in Perth WesternAustralia. I want to create solutions to my problem in the hospitality/ commercial/ home kitchen industry by recreation into new version of modernisation concept into arrange of product in kitchenware to the outdoor/ indoor kitchen lifestyle products. My main purpose of this to be side startup business into future replacement of my full-time job as plasma cnc operator ( kinetic 250 machine.) I haven't got wooden cnc yet but look around. Main concept is to be Australia made / locally made production/ manufactured in Perth WesternAustralia with limited amount of overseas products. All the production will be ideally mostly timber cnc machine with some part injection molding processing/ plasma cnc/ 3d printing for other elements. Try to create eco friendly material base products in recyclables/ repurposing old Australia hard timber wooden guts old karri/blackbutt /Jarrah /spotted grum / iron bark timber( bad piece of timber). On this theme I going to use recyclables/plant base types plastic as well. These products will be all about accessibility/functionality/dual-purpose/ modularised/ portability/ organisatin way into with are mess fre work environment. The conceptof the elements design features in helping people into success . I'm in every aspect very aspect of design the product. All in one unit that dose all the job plus move in around increase value custumerization elements th tocustomer base.

6

6

New comment 2d ago

What CNC Do You Own or Want?

List the make, model & size of your CNC a picture of your workspace (if possible)!! I have: 2 - Laguna IQ's 2x3 1 - Onefinity Elite Foreman 4x4 1 - Laguna Swift 4x8 1 - ShopSabre IS510 5x10 1 - CR Onsrud C Series Dual Head 5x10

Complete action

8

34

New comment 8h ago

4 likes • 9d

I live in Woodford, VA. I retired last year after 43 years of Active Duty Marine Corps (21 years) and Contractor work (22 years). My initial CNC was a no name 3018 desktop CNC with a Laser head. My next CNC was a Standard Router Incorporated industrial 3 phase machine. I have been working through the power conversion and have to get the vacuum repaired but I'm almost there.

0 likes • 5d

@Slim Mab Thank you Slim, it has been an incredible journey to say the least. I bought the 3018Pro desktop in 2018ish and could not get it to carve or laser print out of mirror mode. Yesterday, working with a gentleman at the woodworking shop we were able to fix the G-Code so everything moved and printed in the way we in the Western World read and write. The 3018 was made in China and everything reads right to left so when they code they write the code the same way apparently. We made some initial proof of concepts with the cnc, next is to test the laser on Friday!

My 1st Completed Project

I have made 1st and 2nd iterations of a few projects, but this is my 1st completed CNC project. I'll be presenting it to my youngest daughter at the party before her wedding in Florida on Sunday. Pretty excited about the project. Note: the photo doesn't do the end product justice.

6

4

New comment 5d ago

1-4 of 4

@gregg-lungstrom-5380

Retired Marine looking to learn a retirement gig. I am creating a woodworking class for kid and adults and would like to be able to add the CNC.

Active 2h ago

Joined Oct 27, 2024

powered by